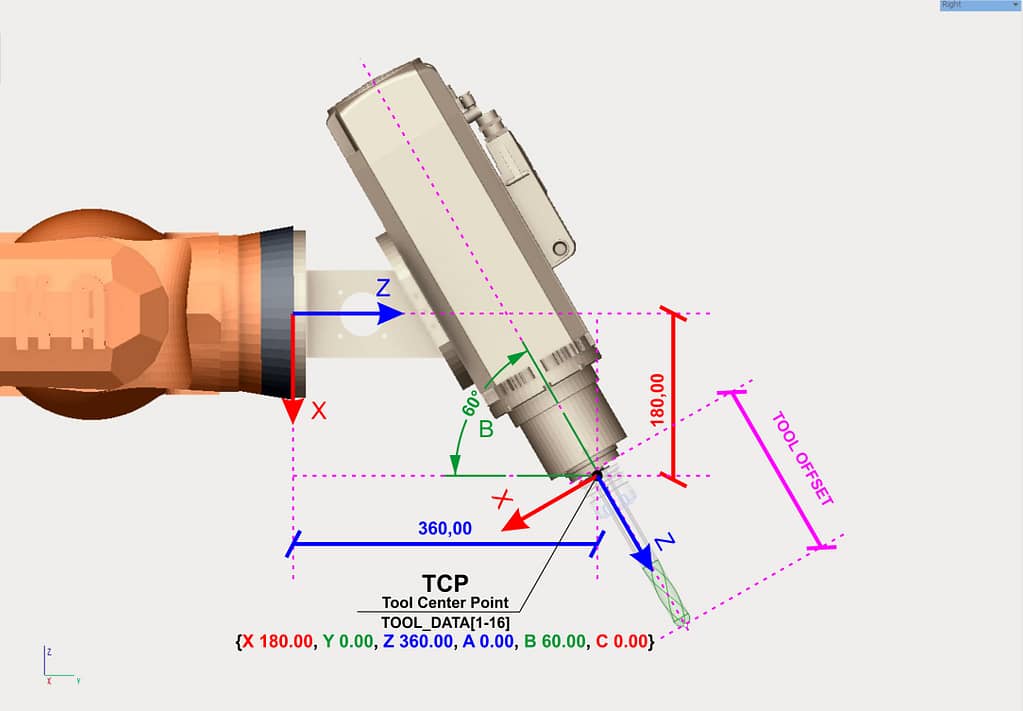

The best and accurate procedure of measuring TCP – Tool Center Point of milling tool or spindle flange. The process consists of two stages. The first one is measuring long probe and the second one is measuring short tool.

- Call internal procedure 4-point method of tool measuring. Menu SETUP > MEASURE > TOOL > 4-POINTS

- Put a sharp static tool in any suitable place for measuring

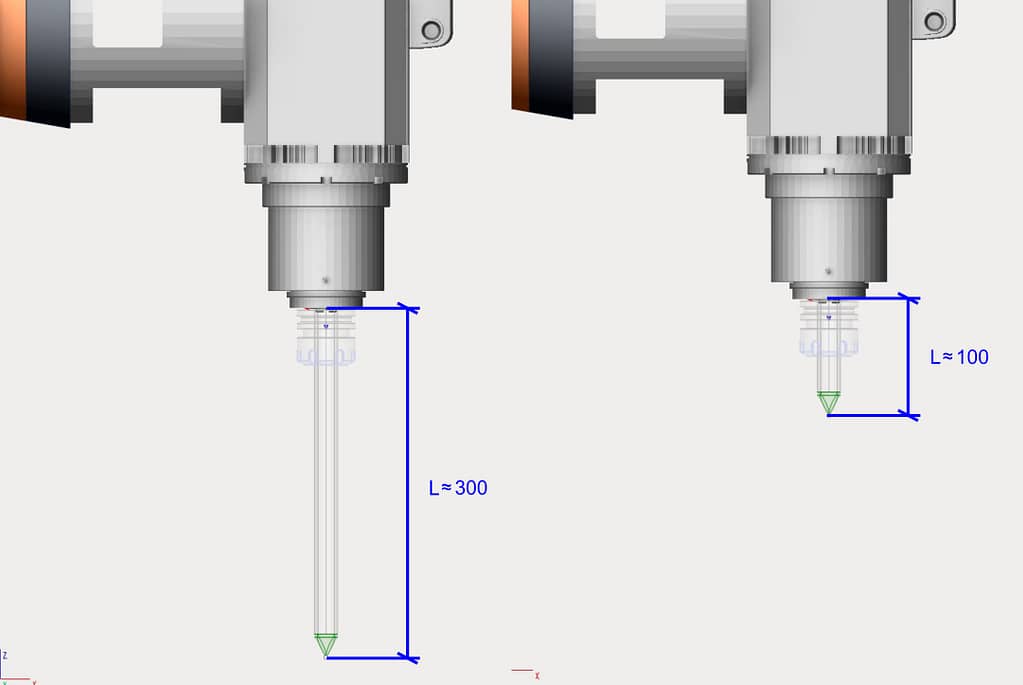

- Insert LONG sharp tool into the spindle. The length of LONG sharp tool might be more then 250 mm.

4. Rotate spindle manually to be sure that a center point of sharp tool doesn’t have any deviations. If there is any deviation turn on spindle, in low speed and using hand file, make it sharp and get rid of deviation.

5. Bring LONG sharp tool to a center of static sharp tool

Press button MEASURE then press NEXT

6. Repeat 3 times 4 – 5 steps after changing position of the tool as on the pictures below.

7. Measure LONG sharp tool 3 times saving tool data to a different variable TOOL_DATA[11-16]

8. Change LONG sharp tool to a short one and measure and save data 3 times.

9. Measure distance of the short tool from the sharp point and to the spindle flange

10. Put all data off LONG and SHORT tool below to calculate a TCP of spindle flange