If you have a tool station and spindle with automatic tool changer you have to set-up the tool clamps before using a program for picking / doping tool holders.

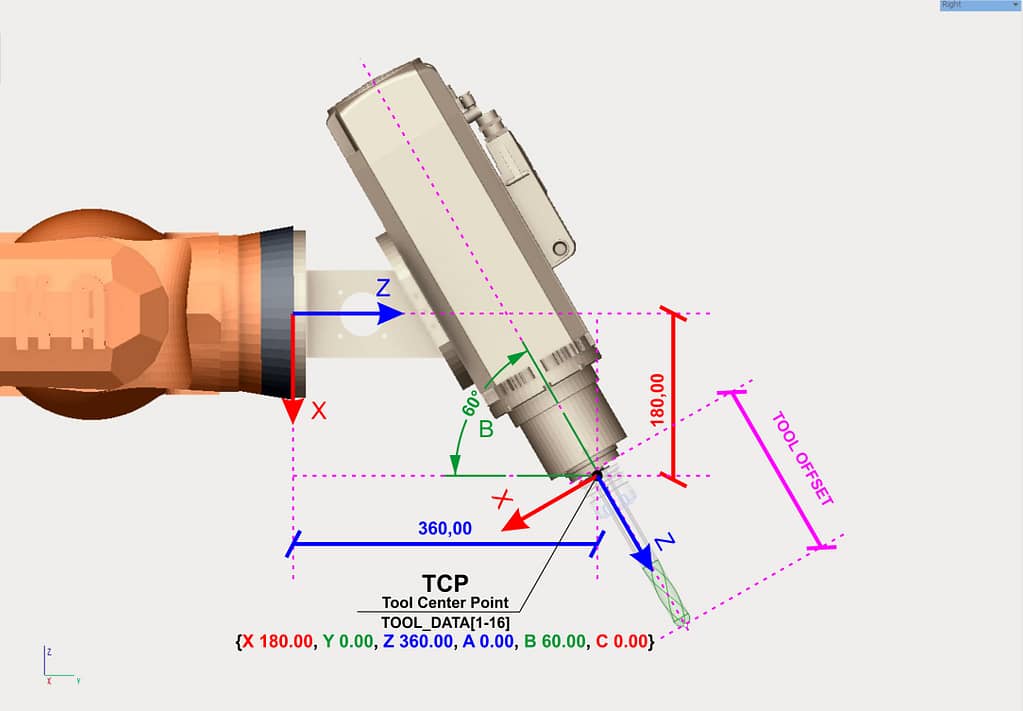

1. Before starting setup a tool station be sure that you have already got a TCP of your spindles flange. Depends of a system version TCP can be stored in variable TOOL_DATA[1] or TOOLD_DATA[16]

2. Set tool in the system

Go to menu CONFIGURE > SET TOOL AND BASE

Put into field TOOL number of TOOL_DATA which stores TCP of the spindle flange.

If you keep TCP data in TOOL_DATA[1] – set number 1

If you keep TCP data in TOOL_DATA[16] – set number 16

BASE must be 0

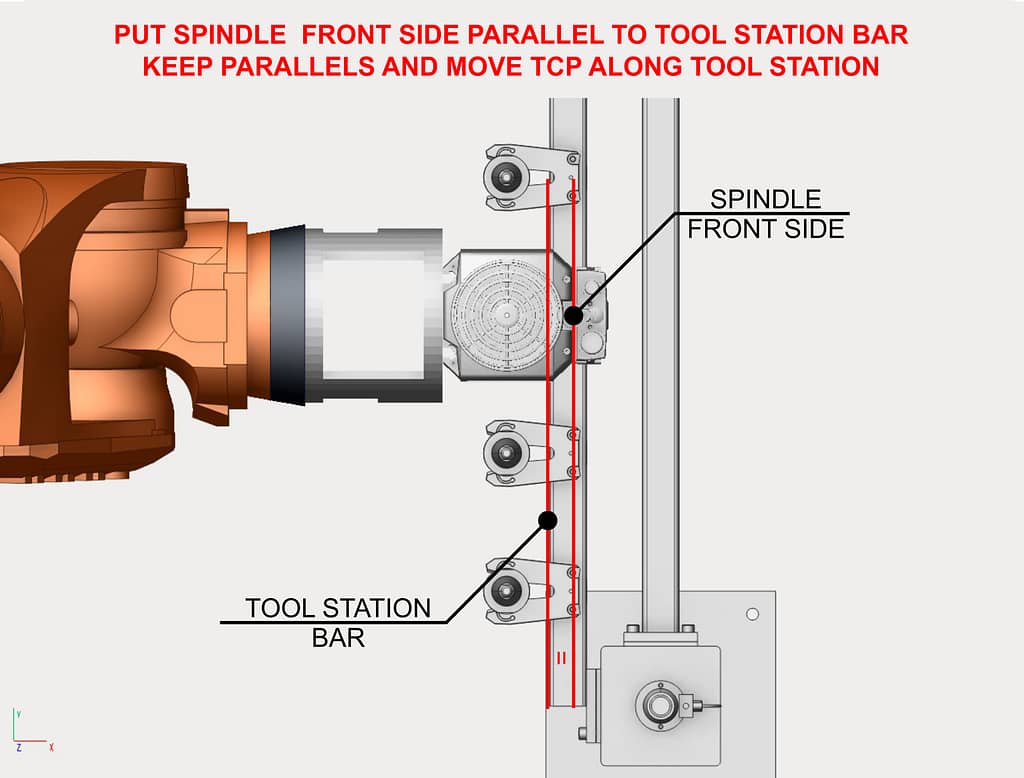

3. Bring TCP to the first tool clamp on the tool station.

4. Select the coordinate system to TOOL coordinate system

5. Open spindle tool locker and move the spindle down according to Z-axis.

!!! Check if the tool locker is opened !!!

Put the spindle flange in the center of tool holder. Use X, Y, Z axis to move and match the centers of the spindle TCP and tool holder.

!!! Do not set jogging speed not more then 10% You can brake tool clamp!!!

6. Before bringing TCP to the point when the spindle can’t move down more, adjust B and C angles.

!!! USE ONLY TOOL coordinate system during adjusting the angles !!!

7. Move the spindle down until spindle can’t move down more.

8. Open MONITOR > VARIABLE > SINGLE

Type in the field NAME a name of variable :

DATA_BASE[number of base of tool holder you are measuring ]

9. Type in the field NEW VALUE – $POS_ACT and press ENTER. After pressing ENTER the data of variable DATA_BASE[number of base of tool holder you are measuring ] will be updated and set the current position of the spindle TCP.

10. Take out the spindle from the tool holder according to Z- axis by pressing button Z –.

!!! Keep attention. You are working in TOOL cordinat system !!!

Pressing Z – spindle moves DOWN

Pressing Z + spindle moves UP

10. Repeat steps from 3 to 9 for all tool clamps. Change VARIABLE name according to a table below.

!!! Each tool clamp has a unique variable. It doesn’t matter which direction you prefer. !!!

11. After getting all data of all tool clamps you need to update an orientation of tool clamps coordinate system.

12. Make an archive file of all configuration and send it to support for validating data.